Max Factor Factory

In 1946, the British Board of Trade released over 300 factories to private industry that had been used during the war effort. One of these – a factory in West Howe, Bournemouth, built to manufacture self-contained radar sets for aircraft – was taken over by Max Factor and Co., Inc. in September, 1946 and repurposed to manufacture cosmetics. It took six months to clear the existing machinery and transform the building, so it was not until June, 1947 that the plant was in full production. Company representatives from Max Factor visited the site in September, 1947, and all but one of the photographs shown on this page were taken then.

West Howe was not the first Max Factor factory in Britain. Beginning in 1936, small plants had been established in London at Park Royal and Acton. These, like many other cosmetic manufacturing operations, had been ‘concentrated’ after 1941 for the duration of the Second World War at shared manufacturing facilities in Croydon.

See also: Max Factor (1930-1945) and Max Factor (1945-1960)

Site

The West Howe factory was situated on Frances Avenue between the Bournemouth Gas and Water Co. and the Northbourne Golf Course. It consisted of two large buildings – designated Factory No. 1 and Factory No. 2 – and a number of smaller buildings that housed the laboratory, canteen, surgery, rest rooms, maintenance, boiler plant, stores, packing departments and other ancillary functions associated with the Max Factor business.

Above: Factory No. 1.

Above: Factory No. 2.

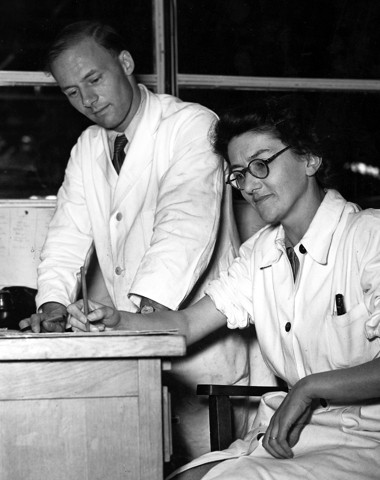

Laboratory

The duties of the laboratory staff included sample testing all deliveries of raw materials, quality checking batches of finished cosmetics, and the compounding of perfumes. All aspects of the laboratory were directed by Frank Atkins, an experienced perfumery chemist.

Above: Interior of the laboratory. Most of the equipment used in the laboratory was supplied by A. Gallenkamp & Co. Ltd.

Factory No. 1

Looking like an aircraft hanger, this building manufactured ‘wet’ cosmetics including cleansing creams, skin creams, face lotions, brilliantines, foundations, cream rouges, lipsticks, eyeshadows and mascara. Tasks were separated largely on gender lines with heavy manufacturing handled by men and light manufacturing and assembly carried out by women.

Above: End view of Factory No. 1. The top floor of the administrative offices can just be seen (right). The doors lead to the Finished Goods Store Room. Over 280,000 cosmetics were made here each month.

Above: Factory No. 1. Two storey office block containing the administration offices.

Above: Factory No. 1. The office of Leonard J. Matchan, European General Manager of Max Factor & Co.

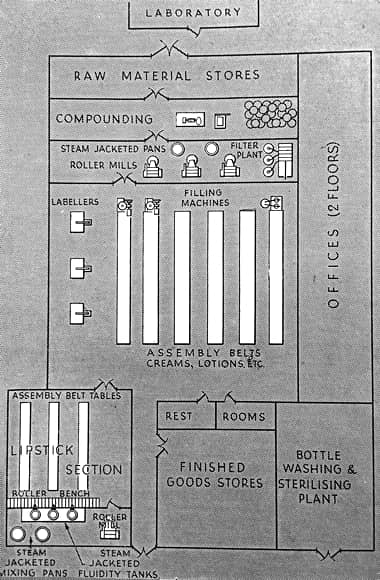

A raw material store was located across the end of the building closest to the laboratory. Next to the material store was the compounding room where the ingredients required for a cream or lotion were measured out according to a given formula before being passed through to the mixing room.

Mixing room

The raw materials to be made into a cream were heated and mixed in steam-heated melting pans after which they were run through a triple-roll mill to ensure that all of the ingredients were completely dispersed. The finished cream was then moved the assembly room where it was poured into jars, labelled and cartoned.

Above: Factory No. 1: Mixing room containing three melting pans (left), heated by steam from the central boiler fed through insulated pipes hanging down from the ceiling, and three roller mills (centre). Behind the melting pans is an electric mixer used to stir the cream mixtures in the melting pans. The two doors to the left lead to the compounding room (one open). The small enclosed space houses the lotion filter press which used the large lotion storage bottles stacked along the side wall.

Above: Factory No. 1: Mixing room photographed from the other side. The side wall holds storage shelves along with a large sink used to clean equipment.

Assembly room

A variety of cosmetics were packaged in this area. It contained five assembly tables – which I will refer to by number – each with a conveyor belt running down their centre. Most assembly processes were done completely by hand but some were partly mechanised.

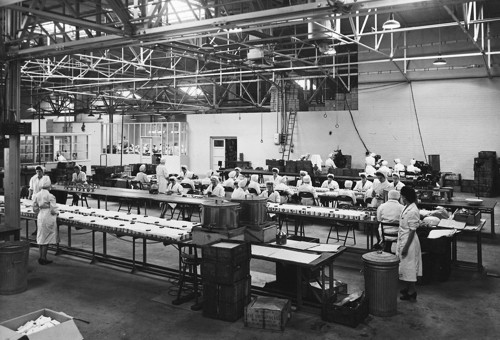

Above: Factory No. 1: Assembly room. The table closest to the camera (assembly table 2) was headed by a gravity-fed filling machine used to pour Invisible Foundation into jars which were then levelled, sealed with silver paper, labelled and capped. On the next two tables (tables 3 & 4) cream jars were filled by a simple hand-held gravity filler which were refilled from a small urn, situated at the top of each line, that kept the cream warm. The back table (table 5) was being used to assemble boxes of mascara. At the back left are two doors that connect through to the mixing room. At the bottom left is a partial view of an additional table (table 1) which was used to assemble bottles of Honeysuckle Skin Cream.

Above: Factory No. 1: Assembly room from the other side. Notice that at least one urn has been moved. When empty, the urns would be light and easily shifted between assembly lines. At the back left is a glassed-in area where lipsticks were made, while on the back wall women are using labelling machines to label bottles of Honeysuckle Skin Cream. A cardboard box full of empty mascara boxes in the foreground marks the position of table 5 (not seen).

Above: Factory No. 1: Assembly room. A closer view of assembly tables 1, 2 and 3. On the back wall are three semi-automatic labelling machines being used on lotion bottles such as Honeysuckle Skin Cream.

Above: Factory No. 1: Assembly room. These women headed the Invisible Foundation assembly line (table 2). The jars were filled by a single worker operating an Albro cream filling machine. The overfilled jars produced by this machine can be seen passing down the central conveyor belt. These were picked up by workers who scraped off the excess into a bowl and then passed the jars to women for cleaning before they were sealed with silver paper.

Above: Factory No. 1: Assembly room. Applying labels to jars of Invisible Foundation which have already been sealed with silver paper (table 2).

Lipstick rooms

Compounding, mixing and assembling lipsticks was carried out in a separate area off to the side of the general assembly area of Factory No. 1. On one side of a dividing wall the lipstick mass was compounded, melted and mixed, after which it was run through a triple-roll mill before being poured into one of three steam-heated tanks where it was kept fluid. These tanks were connected by insulated pipes through the wall to spigots used to fill the lipstick moulds. The metal moulds filled with lipstick were hot and heavy so they were seated on rollers, enabling them to be pushed to where they were cooled with solid carbon dioxide under fans.

Above: Factory No. 1: Lipstick room. Molten lipstick can be seen filling up the holes on one side of the lipstick mould.

Once cooled, the top section of the metal mould was removed to expose the lipstick bases. A Perspex frame, with each hole filled with the bottom half of a lipstick case was then fitted over the exposed bases and the cases were then pushed down to fit the lipsticks into them. The Perspex frame containing the lipsticks was then lifted – freeing the lipsticks from the mould – and passed to an assembly line.

On the assembly line, individual lipsticks were removed from the Perspex frame and placed on a conveyor belt. There they were inspected and had caps added, before being cartoned in boxes of 12 for shipment. Although the process was very labour intensive, this room could produce up to 12,000 lipsticks per day.

Above: Factory No. 1: Lipstick room. Three women are removing individual lipsticks from their Perspex frame before placing them on the conveyor belt. A team like this headed each lipstick assembly line. Some lipsticks appear to have been removed from the line which suggest that the women were inspecting the sticks for imperfections and removing faulty items.

The lipsticks produced at the Bournemouth factory were 13 mm in diameter where previously – before and during the war – Max Factor had only made 9 and 11 mm versions. The moulds came from the United States where 13 mm lipsticks been made for some time. The metal cases for the lipsticks – which differed from those in America at the time – were made on the Bournemouth site by a manufacturer with a contract with Max Factor. Max Factor would later switch to Edward Webster Ltd., West Howe.

Above: Factory No. 1: Lipstick room. On the left wall can be seen two of the three spigots used to pour the molten lipstick mass into the metal moulds. On the other side of this wall the mixing, heating and milling of the lipstick mass took place. The door between these two rooms is to the left and is not visible in this photograph. Only two assembly lines are being used to make lipsticks. At the top of each line three women removed the individual lipsticks from their Perspex frame and placed them on the conveyor belt running down the middle of each table. Other workers then inspected and cleaned the lipsticks, added caps and a shade label, and then cartoned the lipticks in boxes of a dozen each. Unusually, there are no spirit burners or other heating devices – normally used to remove moulding imperfections – on the tables.

See also: Lipsticks

Factory No. 2

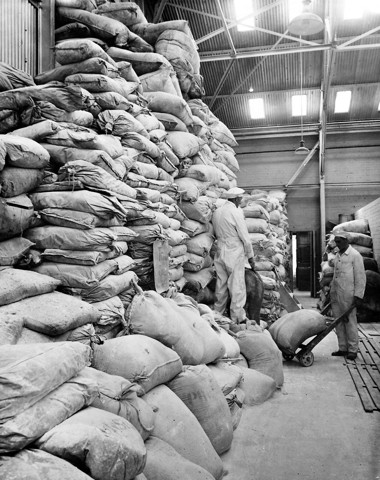

This factory manufactured a range of ‘dry’ cosmetics including face powders, compact rouge and Pan-Cake make-up. As with Factory No. 1, tasks were separated on gender lines with most of the heavy work done by men.

Above: End view of Factory No. 2. A truck is loading goods from the Export Packing Department (right). The other roller door looks like it connects to the Finished Goods Store.

Mixing room

Colours used in the make-up products at West Howe were measured out in a special room at one end of this factory according to set recipes. The colours were mixed wet by hand on trays, then dried in an oven, after which they were ground in a ball mill, sifted, passed through a micropulveriser and then remixed with a perfume if required.

The mixing room in Factory No. 2 – next to the colour chamber – contained a large amount of heavy machinery including two large mixing and sifting machines, three smaller mixers, and three micropulverisers.

Above: Factory No. 2: Mixing room. On the right a worker stands on top of one of two large mixing and sifting machines used for the large scale manufacture of face powder. The other two workers are feeding raw materials into micropulverisers. To the left of each micropulveriser is a small mixer used to make smaller batches. A door (bottom left) leads to a short corridor that runs between the powder filling and Pan-Cake press rooms next door.

Above: Factory No. 2: Mixing room. A closer view of a worker feeding a micropulveriser from a large can. The rectangular machine on the right is one of the smaller mixers made by Gardner & Sons Ltd.

See also: Loose face powders

To prevent powder from drifting through the factory the rouge press, Pan-Cake press and a powder filler were each housed in separate rooms situated between the mixing and assembly rooms.

Rouge press room

In 1948, rouge at the West Howe factory was only made in nine shades. Max Factor had thirteen shades of rouge at the time so it is possible that post-war restrictions limited production to those that matched the Max Factor lipsticks; i.e., Clear Red, Blue Red and Rose Red each in three tones. An automatic rouge press made six cakes of rouge at each a press with each tablet of compressed rouge being impressed into a small metal pan or godet.

Above: Factory No. 2: Rouge press room. A close-up of the rouge press. The rotating metal plate has been finished with depressions used to make compressed rouge. Metal godets were added to each of the six depressions in each set (left), these were then filled with powder mixed with a binder (front right), put through the press (right), then lifted from the moulds (back). Piles of empty metal godets can be seen at the front while at the back a worker removes the competed compact rouge cakes with a pointed instrument and piles them up ready to be laid out in trays to dry.

See also: Compressed face powders

As the completed rouge cakes were slightly damp they were placed on trays to dry out before being passed to the assembly room to be fitted into plastic containers and cartoned for shipment.

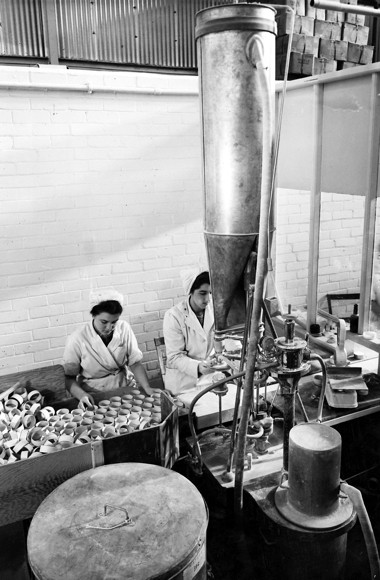

Pan-Cake press room

Pan-Cake was made in 12 shades in two sizes at the West Howe factory. There were two Pan-Cake presses in this room, each of which required a worker to inspect and load the metal godets and a second person to operate the press. Once made, the competed cakes were passed to the assembly room by conveyor belt for packaging, labelling and cartoning.

Powder filler room

Face powder was made in 18 shades in three sizes. Albro powder filling machines were used – one single-headed, the other double-headed – to fill boxes with powder. The completed boxes were then passed by conveyor belt into the assembly room for packaging, labelling and cartoning.

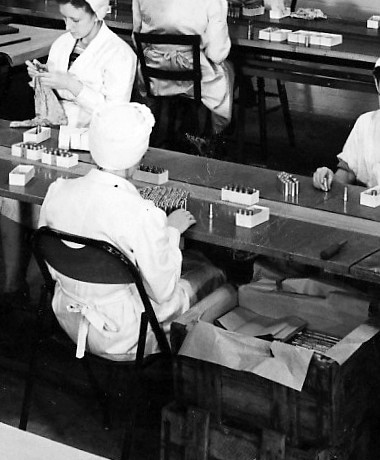

Assembly room

The Factory No. 2 assembly room contained five assembly tables – each with a conveyor belt running down the middle – which I will again refer to by number.

Above: Factory No. 2: Assembly room. The closest table (table 2) is assembling face powders, the next two (tables 3 & 4) produce Pan-Cake make-up, and the last (table 5) is being used to assemble compact rouge. At the top of each table can be seen glassed-in rooms which, from left to right, contain the rouge press, two pancake presses, and two powder fillers. Another table (table 1), also used to assemble boxes of face powder, is not visible.

Above: Factory No. 2: Assembly room. A closer picture of assembly tables 2 & 3. The corridor between the rooms containing the two pancake presses and the two powder fillers can be seen – this leads via a door to the mixing room. The woman standing at the top of the Pan-Cake assembly table is probably the Factory Supervisor for Factory No. 2 (name unknown).

Above: Factory No. 2: Assembly room. Trays of compact rouge disks are being packaged, labelled and cartoned on table 5.

Export

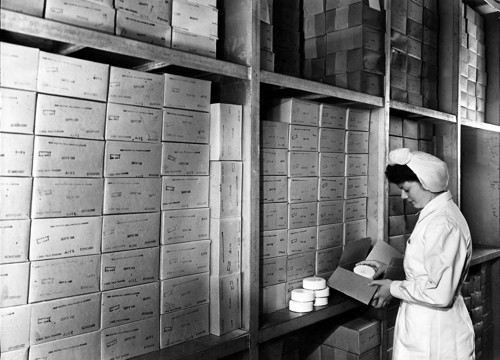

Up to 12,000 boxes of face powder, 90,000 rouge compacts and 140,000 compacts of Pan-Cake could be produced in Factory No. 2 each day. Many of these, along with the output from Factory No. 1, were destined to be exported from Britain to Europe and those parts of the British Commonwealth – such as Singapore – that did not have facilities to manufacture Max Factor cosmetics.

Above: Cosmetics cartoned and ready for export.

Industrial development was important to the economic recovery of post-war Britain. It provided employment for over 500 workers and exports from the factory also contributed to badly needed foreign currency reserves. Manufacturing in Britain in the late 1940s was highly regulated – the country was still on rationing – and Leonard Matchan, European General Manager of Max Factor & Co. – who was also the Chairman of the Toilet Preparations and Perfumery Manufacturers’ Federation – lobbied the British Board of Trade about the importance of the cosmetics and toiletry business. This helped free-up some of the restrictions the government placed on their manufacture.

Later developments at the site

In 1959, Max Factor upgraded the Bournemouth site with new manufacturing facilities and office buildings. Although some processes were mechanised, production remained largely labour intensive.

Above: The compounding room in the new factory completed in 1959. Operations are now on a much larger scale and, although still labour intensive, are more automated.

A second redevelopment of the site was completed in 1974 after Max Factor merged with Norton Simon.

Updated: 30th May 2019

Sources

deNavarre, M. G. (1941). The chemistry and manufacture of cosmetics. Boston: D. Van Nostrand Company.

Hollywood make-up produced at Bournemouth. (1948) Manufacturing Chemist and Manufacturing Perfumer. XIX(2), 49-58.

1947 Max Factor Hollywood & London. Some of the products that will be made in the factory.

Leonard J. Matchan [1911-1987], European general manager of Max Factor & Co.

Edward Davies, the production manager in charge of the entire manufacturing plant.

Frank Atkins, was in charge of the laboratory and blending the perfumes used in the cosmetics.

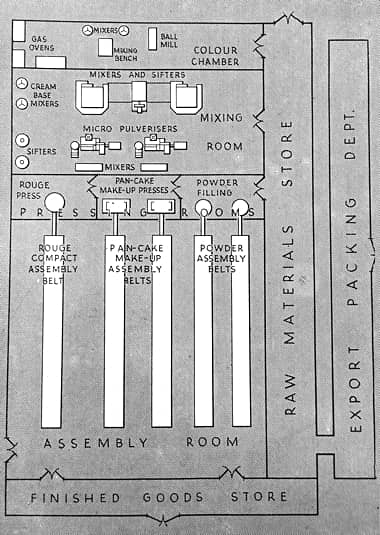

Plan of Factory No. 1 (Hollywood make-up produced at Bournemouth, 1948). This plan is not accurate or to scale. An entire storeroom on the left of the plan is missing, doors are left out, the assembly room shows six tables instead of the five in operation at the time, at least one of the rest rooms is an office, and there were three steam-heated melting pans being used not two as shown.

Factory No. 1: Mixing room. A worker pouring cream from one of the steam-heated mixers in the cream mixing room. After being mixed the creams were passed through the triple roller to ensure that all the ingredients were fully dispersed.

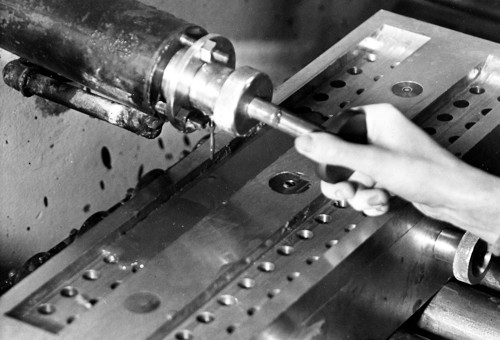

Factory No. 1: Mixing room. A triple mill in operation.

Factory No. 1: Assembly room. Jars of Invisible Foundation are being assembled. One woman operates the Albro cream filler (front right) but as this machine overfills the jars the next three women on the line have to scrape off the excess into a bowl. The jars were then passed to workers who cleaned the tops of the jar and readied them for a silver cap. Four women applied silver paper to seal the jars; three women added tops, with two of those then packing the jars into boxes.

Factory No. 1: Assembly room. Worker operating the cream filling machine from Albro Fillers and Engineering Co. Ltd. on the Invisible Foundation assembly line.

Factory No. 1: Assembly room. Four workers are using hand-held gravity fillers to fill jars of cleansing cream. One woman is replenishing her hand-held filler from the dispensing urn used to keep the cream warm. After the jars are filled and allowed to cool slightly, lids were then added by hand.

Factory No. 1: Assembly room. Operation of a simple gravity filler.

Factory No. 1: Assembly room. Putting together boxes of cake mascara on assembly table 5. Each box required a block of mascara, a brush, a set of instructions and a shade label.

Factory No. 1: Assembly room. A worker fills bottles of Honeysuckle Skin Cream – soon to be renamed Astringent Foundation. The bottles have already been labelled by one of three labelling machines. Mrs. Williams, the Factory Supervisor looks on.

Factory No. 1: Lipstick room. Three steam-heated lipstick vats keep the lipstick fluid as it is fed through the wall to spigots used to dispense the lipstick into moulds.

Factory No. 1: Lipstick room. At the back a worker in a dark uniform is using fans to cool down a filled lipstick mould. Directly behind her another woman, also in a dark uniform, adds metal bases to the lipsticks housed in a Perspex frame. Once this was done she would then lift the Perspex frame from the mould and pass it on to one of the lipstick assembly lines.

Factory No. 1: Lipstick room. Inspecting lipsticks for imperfections.

Factory No. 1: Lipstick room. A worker adding caps to lipsticks from a box of empty lids to her right.

Factory No. 1: Lipstick room. The woman at the front is adding a shade label to the bottom of each lipstick case. Max Factor only named three shades of lipsticks in Britain in 1948: Blue Red, Clear Red and Rose Red, each of which came in three different tones numbered 1, 2 and 3 making a total of nine shades.

Mr. R. Armitage, Assistant Production Manager and Mrs. Williams, Factory Supervisor of Factory No. 1.

Plan of Factory No. 2 (Hollywood make-up produced at Bournemouth, 1948). This plan is not to scale and a corridor between the Pan-Cake press room and the powder filling room is missing.

Factory No. 2: Powder store room.

Factory No. 2: Rouge press room. The woman to the left is adding metal godets to the press while the women at the back is removing the completed compressed rouges.

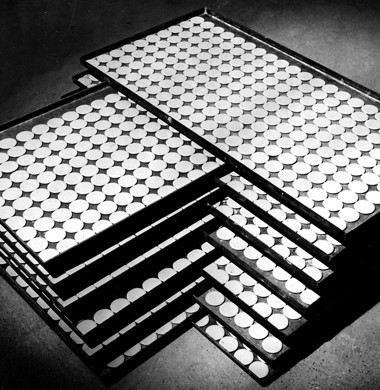

Above: Trays of completed rouge cakes.

Factory No. 2: Pan-Cake press room. The worker at left is cleaning and feeding godets to the machine which fills them with Pan-Cake powder and compresses them. Once made, the Pan-Cake discs pass out right where a woman appears to be brushing each cake as it leaves the press, either to remove any stray particles or possibly to give the cake a more matt finish.

Factory No. 2: Powder filling room. An Albro Powder Filler is being used to fill powder boxes. This system used vacuum pressure to draw powder from the hopper above the operator, filling the boxes with the desired amount of powder while keeping dust levels low. The filled boxes were then placed on a conveyor belt which fed directly to assembly table 1 (right).

Factory No. 2: Assembly room. This second assembly line for face powders used a single-headed powder Albro filler. The large-sized powder boxes are passed by conveyor belt through a small window from the powder filler room to assembly table 2 where lids were added. The powder boxes were then cleaned to remove any surface powder and lingering static electric charge, and their weight was checked.